Equipment failures cost Life Science companies millions and always strike at the worst possible time. Traditional monitoring 1.0 systems alarm only after damage is done—when repairs cost 3x more and products or research is already lost. TRAXX Predictive Failure Analytics identifies mechanical stress and potential failure risks before they cause catastrophic losses. When repairs can be planned, they are less expensive and less disruptive to operations.

See Problems Before They Become Catastrophes

TRAXX AI identifies failure patterns hours, days or weeks before catastrophic breakdown, transforming reactive maintenance into predictive prevention.

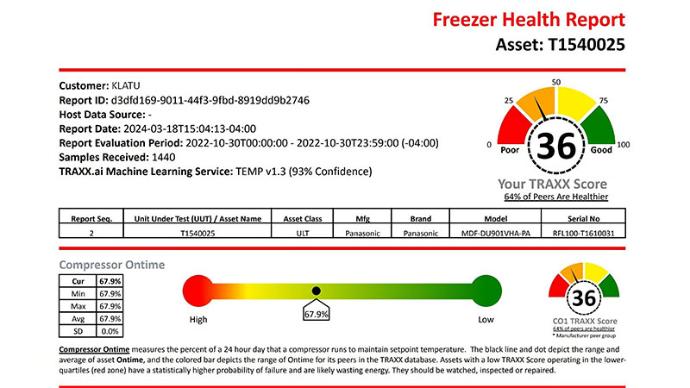

Introducing TRAXX Score: How TRAXX Predicts Failures

The power of TRAXX AI to predict failures is based on our patented TRAXX Score—it's like a FICO score, except for equipment. We use TRAXX AI to measure and benchmark the performance of each asset against its peers to identifying which assets need immediate attention and which can safely defer maintenance.

AI Models Trained on 100+ Billion Data Points

Ten years of sensor data from hundreds of equipment makes and models enables TRAXX to predict failures from just hours of data—without waiting for anomalous events that other systems require.

Prevent $2.5M Catastrophes.

In a documented case, TRAXX delivered a critical hours early warning of compressor failure on a weekend, preventing a $2.5 million product loss—weeks before conventional monitoring systems would have triggered any alarm.

Explore other TRAXX Applications

Ready to Predict and Prevent Equipment Failures?

Join the life science leaders who've already prevented millions in equipment failures.