Predictive Analytics that makes sense.TRAXX AI transforms your equipment maintenance from Fail-and-Fix™ to Predict-and-Prevent™ management.

Using machine learning models trained on your assets' physical sensor data, TRAXX AI

create digital representations of your equipment and compare performance to peers of

similar makes and models

in our database

. Think of it like an EKG for your equipment—when

vital signs change from normal, TRAXX alerts you before it becomes a problem.

Our models recognize equipment behavior patterns

using only physical sensor data—temperature, energy consumption, door activity,

and surrounding HVAC performance—never personal information.

Digital TWINS + POPULATION BENCHMARKING

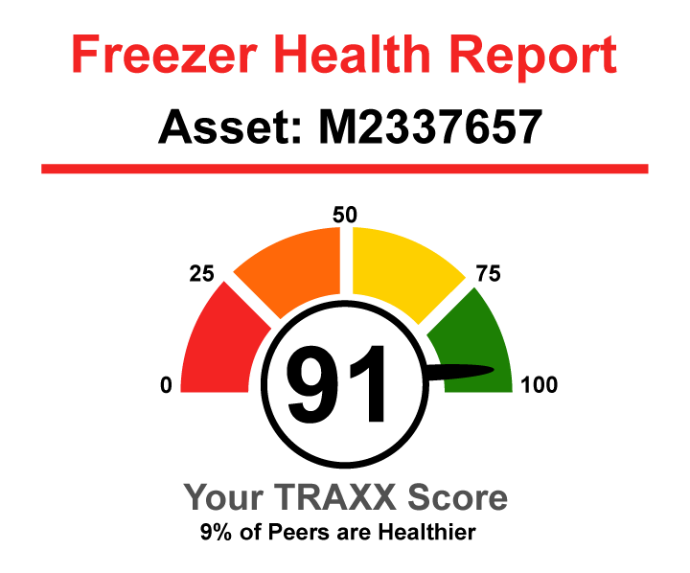

TRAXX Score

TRAXX Score works like a FICO® credit score—but for your equipment. Instead of waiting for problems to occur, it instantly compares each asset's performance against optimal benchmarks from our 100+ billion record database.

Each cold-storage system receives multiple TRAXX Scores that provide objective measurements of mechanical health, energy efficiency, utilization patterns, temperature stability, and repair effectiveness.

Low TRAXX Score

Scores of 26-50 indicate developing issues like wasting energy or at risk of mechanical failure, requiring inspection. Scores below 25 need immediate attention to prevent failure.

High TRAXX Score

Assets scoring 76-100 are performing optimally and can safely defer maintenance.

This benchmark scoring helps you prioritize maintenance spending and schedule repairs strategically.

BRING YOUR OWN DATA

Integration Options

Already have monitoring systems that work well for basic reports and alarms? TRAXX AI 2.0 deploys by allowing you to 'Bring Your Own Data' (BYOD) from any existing monitoring system without disrupting validation protocols .

Our flexible architecture connects seamlessly to OSIsoft/AVEVA™ PI, Building Management (BMS) systems, MQTT data sources, and CMMS platforms via API integration or CSV upload.

TRAXX platform adapts to your IT environment and security requirements while unlocking predictive analytics capabilities.

THE ECONOMICS OF PREDICTIVE MAINTENANCE

ROI Analysis

TRAXX customers typically see ROI within 6-12 months through multiple value streams. By shifting from reactive to predictive maintenance, organizations eliminate the hidden costs of equipment failures while optimizing operational efficiency. The financial impact comes from several key areas where TRAXX directly reduces expenses and extends asset life.

Repair Cost Reduction

30% savings by catching issues early vs. post-failure repairs

Energy Savings

20% reduction by identifying inefficient operation

Downtime Prevention

Eliminate unplanned failures that cost 3x more than scheduled maintenance

Asset Life Extension

Proper maintenance extends equipment life by 2+ years

Risk Mitigation

Avoid catastrophic product losses that can exceed $1M per incident

Sustainability

Document energy savings for utility rebates and green certifications

Calculate Your Potential ROI.

Discover how much TRAXX could save your organization through predictive maintenance and energy optimization.